products

Contacts: Li Sheng

Telephoneпјҡ18150992829

Faxпјҡ0595-88056969

Address: Jinjiang Cizao Fujian city of Quanzhou Province east slope money 205205

products

Contact us

|

It can be plated with Au,Cu, Al,Cr,Ni stainless steel high temperature, low temperature, corrosion resistance, decorative protective film, and can be plated with ultra-hard film such as Tic. It is widely used in machinery, light industry, electronics, national defense and other fields, film layer.

Smooth surface to dense, improve hardness, wear resistance, anti-corrosion, beautification decoration.

This equipment has high dissociation rate, fast film forming speed and low temperature, and its main size is based on user's choice.

дёҖпјҡPlating color of stainless steel coating machine

Wire drawing effects: copper, brass, golden, smoky gray, brown, anti fingerprint The hair, anti fingerprint The hair black, anti fingerprint The hair BRONZE, anti fingerprint The hair etch and so onгҖӮ

Satin effect: rose gold, disordered hair, silver white and so on.

Mirror face effect: Mirror purple copper, mirror brass, mirror face rose gold, mirror gold, mirror face black, mirror face ancient copper, mirror face purple, mirror face blue, mirror face wine red, mirror face champagne gold, 8K mirror panel, mirror etching, mirror etchant of copper, mirror etched rose gold, mirror etching gold gold, mirror etched gold There is love.

Sand blasting effect: sanding plate, sand black, etc.

And grain effect: with the stripe, and some copper, etc.

3D effect: 3D board, gold 3D.

дәҢпјҡStainless steel vacuum coating machine application

1. The stainless steel Ion plating machine

This series of equipment is safe, environmental protection, stable process, rich color, uniform color, corrosion resistance, corrosion resistance, high temperature resistance, and adhesion is not easy to fade.гҖӮIt should be widely used in stainless steel plate, stainless steel pipe (the longest 6 meters) stainless steel exhibits, stainless steel LOGO sign, lock, pull hand, hardware bath, stainless steel tableware and other stainless steel products and plastic plating, ceramics and other surface coating technology

The stainless steel plate ion plating machine specializes in the design of the stainless steel decorative plate ion plating coating. The ion coating has a real metal texture, which is incomparable to the electroless plating of stainless steel.

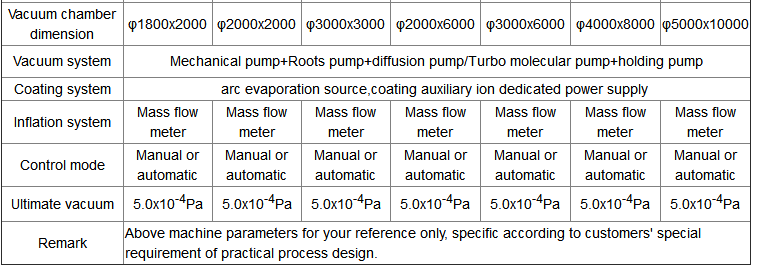

The diameter of the series of equipment is 1800-2300 high 3600-4400. It can produce 3 1220*4000MM plates each time, with three sets of large pumping speed vacuum units, fast pumping speed, short working cycle, 34-56 circular arc targets, reasonable target design, pulse bias system, good film binding force, uniform color color, and touch screen +PLC, which can realize electricity. Automatic brain control, automatic / manual switching at any time, reliable and stable operation performance.

This series of equipment safety, environmental protection, stable process, the coating color is rich, colour and lustre is uniform, wear resistance, corrosion, high temperature resistance, good adhesion and not easy to fade, making Tin plating titanium decorative film: Tic, CrC, gun black, black, gray film series, ZrN zirconium gold, champagne gold, coppery series film layer; TiCN rose gold

Rose red, wine red, coffee color and other series of layers, Tio gem blue, green, pink, rainbow, rainbow, rainbow color series should be widely used in stainless steel sheet, stainless steel pipe, stainless steel exhibits.

Stainless steel LOGO signs, locks, handle, hardware bathroom, stainless steel tableware and other stainless steel products and plastic plating parts, ceramics and other surface coating technology.

2.Horizontal large stainless steel vacuum coating machine.

The equipment is mainly used for building hardware decoration, furniture, lamps and lanterns, hotel appliances, automobile, aviation and other products.

The horizontal large stainless steel coating machine is specially designed for stainless steel decorative plate ion plating. The ion coating layer has real metal texture, which is a series of equipment which is not comparable to the chemical plating stainless steel.

The diameter of the series of equipment is 1800-2300 high 3600-4400. It can produce 3 1220*4000MM plates each time, with three sets of large pumping speed vacuum units, fast pumping speed, short working cycle, 34-56 circular arc targets, reasonable target design, pulse bias system, good film binding force, uniform color color, and touch screen +PLC, which can realize electricity. Automatic brain control, automatic / manual switching at any time, reliable and stable operation performance.

3.Large plate tube vacuum coating machine.

In the vacuum chamber, the vaporization or reactants are deposited on the substrate by gas discharge or partial vaporization of the vaporized substance, while the vaporization or reactants are deposited on the substrate, which greatly improves the film's quality, and also expands the application range of the film. The film has strong adhesion, good winding and wide membrane.

The working principle of the vacuum coating machine is that the ion plating is partial ionization of the gas discharge or evaporation material in the vacuum chamberпјҢThe evaporation or reactant is deposited on the substrate while the gas ion or the particles of the evaporation are bombarded.Ion plating combines the glow discharge image, plasma technology and vacuum evaporation together in three ways.Not only can obviously improve the quality of the membrane, but also expand the application scope of Thin film.

The advantage is that the film has strong adhesion, good winding property and wide membrane material. Multi arc ion plating is very different from ordinary ion plating. Arc ion discharge is used in multi arc ion plating.

Application: a variety of metal films, such as stainless steel, chromium, titanium, tungsten, etc., can be plated to make alloy films or compounds, such as Tin/Tiain/CrN, for stainless steel plate, stainless steel tube, and other workpiece surface coating.

Characteristicпјҡ

* equipped with low temperature ion auxiliary source, without heating, cold direct deposition at room temperature, energy saving and power saving.

* the maximum size of the vacuum chamber can be 5000*10000 long.

* is in the large plate, tubing in making all kinds of decorative film plating layer and function of membrane membrane will choose equipment

Low temperature ion assisted coating source

* large area ion discharge, high ionization effect, high bonding strength and strong adhesion.

* the distribution of ions is uniform, which greatly improves the stability and uniformity of the film layer.

* the effect of ionization is good, without heating the film directly, removing the traditional heating device, saving more than 30% of electricity, saving over 10% of the coating time, improving the efficiency and realizing the low temperature coating.

* play the ionization effect directly, whether metallic plating, non-ferrous metal or non-metallic plating directly coating.

* good ionization effect, whether stainless steel products or non-ferrous metal products (such as copper, aluminum, zinc, magnesium, etc.) do not require Water plating direct vacuum coating.

* it is the first choice of equipment for coating all kinds of decorative films and functional coatings on large plates and pipes.

4Stainless steel plate titanium furnace.

5.Special vacuum coating machine for rose gold.

6Stainless steel black titanium vacuum coating machine.

7.Vacuum coating machine for horizontal stainless steel tube

Horizontal stainless steel pipe coating equipment safety, environmental protection, process stability, the film layer color is rich, color uniformity, wear resistance, corrosion, high temperature resistance, good adhesion and no fading.

Coating method: hanging plating

Length: 1.0-6.0 m.

Follow the official WeChat

Follow the official WeChat