products

Contacts: Li Sheng

Telephoneпјҡ18150992829

Faxпјҡ0595-88056969

Address: Jinjiang Cizao Fujian city of Quanzhou Province east slope money 205205

products

Contact us

|

Plating products

1. Building hardware: bathroom hardware (like water bibcock). Door lock. The door handle. Wei yu, hardware joint leaf, furniture and so on.

2. Watchmaking: can be used in case. The coating and crystal products of the band.

3. Other hardware: leather hardware. Stainless steel tableware. Frames, knives, molds, etc.

4. Large workpiece: automobile wheel hub, stainless steel plate. Brand. Sculptures, etc.

5. Stainless steel tubes and plates (various types of surfaces)

6. Furniture, lighting and hotel appliances.

7. Lock, handle, hardware, golf head, stainless steel tableware, utensils and other hardware products plated super hard decorative film.

Accessories such as watches, watchbands, eyeglasses and jewelry are plated with ultra-wear-resistant decorative (gold and silver) nanomaterials and nanomaterials and nanomaterials.

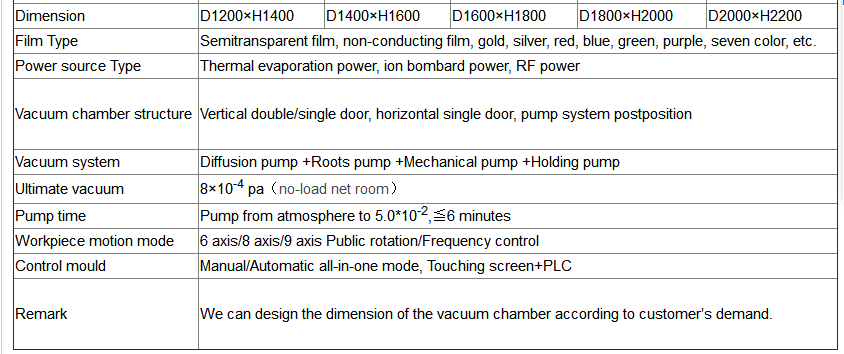

дёҖ:Evaporation vacuum coating machine.

1. Vacuum evaporation coating equipment is used in the vacuum chamber electric heating Yin, the metal plating material melt, evaporation, let metal molecular deposition on the substrate, to obtain smooth high reflective metal film layer, adornment beautification the purpose of the object surface

2. vacuum evaporation coating equipment has the advantages of reasonable structure, large pumping speed, short working time, high production efficiency, convenient operation, low energy consumption, stable work, uniform film and good film quality. The equipment is widely used in automobiles, audio, various small household appliances, computers, clocks, mobile phones, reflective cups, cosmetics, toys and other industries.

3. Available materials include :ABS,PS,PP,PC,PUV,TPU, nylon, glass, ceramics, metal, etc.

4. can be plated substrate surface state: bright surface, matte surface (semi dumb, full dumb), process plating wrinkles, drawing, raindrops, etc., plating color, gold, silver, red, blue, green, purple, colorful, etc.

It can be used for vacuum coating machines of all sizes, and the vacuum system can be matched.

дёүhorizontal Evaporation vacuum coating machine.

1. It is widely used in automobile, acoustics, all kinds of small appliances, computers, clocks and watches, mobile phones, reflective cups, cosmetics, toys and other industries.

2. Machinable materials include: ABS, PS, PP, PC, PUV, TPU, nylon, glass, ceramics, metal, Boli, etc.

3. The plating effect is electroplated bright surface, matte surface (Dumb face,), process electroplating wrinkle, drawing, raindrop, etc., plated with color, gold, silver, red, blue, green, purple, seven color, etc.

It can be used as vacuum coating machine of various sizes, and the vacuum system can be optional.

еӣӣ:Non conductive (NCVM) coating machine

1. non conductive (NCVM) film coating machine is the use of electric cathode heating in the vacuum chamber, molten metal materials, gas, metal molecules deposited on the substrate, to obtain a smooth and high reflective metal film, to achieve the purpose of ornament and beautify the surface of the object.

2. vacuum evaporation coating equipment has the advantages of reasonable structure, large pumping speed, short working period, high production efficiency, convenient operation, low energy consumption, stable work, uniform film and good film forming quality.

Widely used in plastic electronic products, mobile phone shell, mobile phone buttons, computers, digital, electronic communications and other surface plating non-conductive film (NCVM)

It can be used in various sizes vacuum coating machine, vacuum system can be selected.

дә”:Double door vacuum coating machine.

1. The double door vacuum coating machine is used to film the glass by means of the evaporation of the cathode.In the vacuum chamber, the through resistance wire is heated, and the metal material (aluminum wire, chrome nickel, etc.) affixed to the cathode wire is Melting vaporizing.Vaporized metal molecules are deposited on the surface of glass substrate to form a metallized reflection surface. The purpose of glass mirror mirror is reasonable structure, large pumping speed, short working period, high production efficiency, convenient operation, low energy consumption, stable work, uniform film and good film quality.

е…ӯ:Colorful vacuum coating machine.

1. Vacuum evaporation coating equipment is used in the vacuum chamber electric heating Yin, the metal plating material melt, evaporation, let metal molecular deposition on the substrate, to obtain smooth high reflective metal film layer, adornment beautification the purpose of the object surface

2. vacuum evaporation coating equipment has the advantages of reasonable structure, large pumping speed, short working time, high production efficiency, convenient operation, low energy consumption, stable work, uniform film and good film quality. The equipment is widely used in automobiles, audio, various small household appliances, computers, clocks, mobile phones, reflective cups, cosmetics, toys and other industries.

3. Available materials include :ABS,PS,PP,PC,PUV,TPU, nylon, glass, ceramics, metal, etc.

4. can be plated substrate surface state: bright surface, matte surface (semi dumb, full dumb), process plating wrinkles, drawing, raindrops, etc., plating color, gold, silver, red, blue, green, purple, colorful, etc.

It can be used for vacuum coating machines of all sizes, and the vacuum system can be matched.

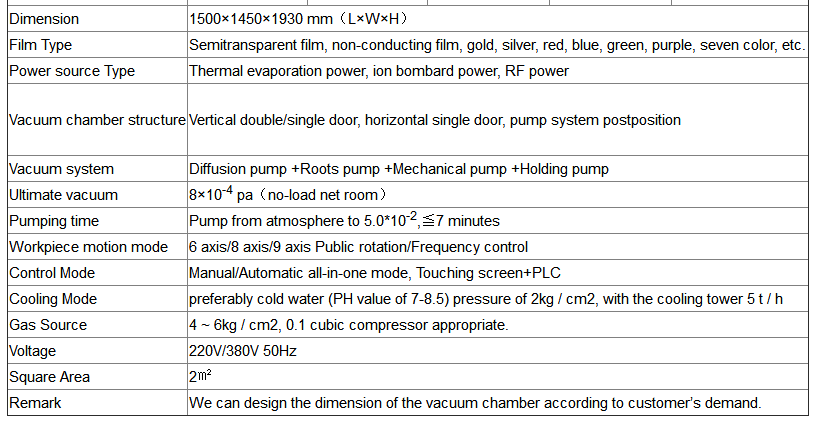

дәҢ:Small experimental vacuum coating machine

1. Application: surface coating for scientific research, teaching, electronic components, and coating production.

2.It is suitable for any color - plated plastic, ceramic, resin process, glass and so on. After vacuum coating, it can be plated into gold, silver, red, blue, green, purple, seven color, grey, black and other colorful colors, which can improve the grade of the product and make the appearance more magnificent.The vacuum coating machine has the advantages of beautiful appearance, compact structure, small floor area and easy maintenance. It can be fully automated or manual controlled by experiments, and is simple and reliable.Various coating process parameters can be automatically completed by Electric Yin evaporation coating, arc plating or magnetron sputtering. No matter which coating method can be used in scientific research, electronic components, and coating production, the surface coating can be electroplated aluminum, tin, chromium and so on.

Follow the official WeChat

Follow the official WeChat