products

Contacts: Li Sheng

Telephoneпјҡ18150992829

Faxпјҡ0595-88056969

Address: Jinjiang Cizao Fujian city of Quanzhou Province east slope money 205205

products

Contact us

|

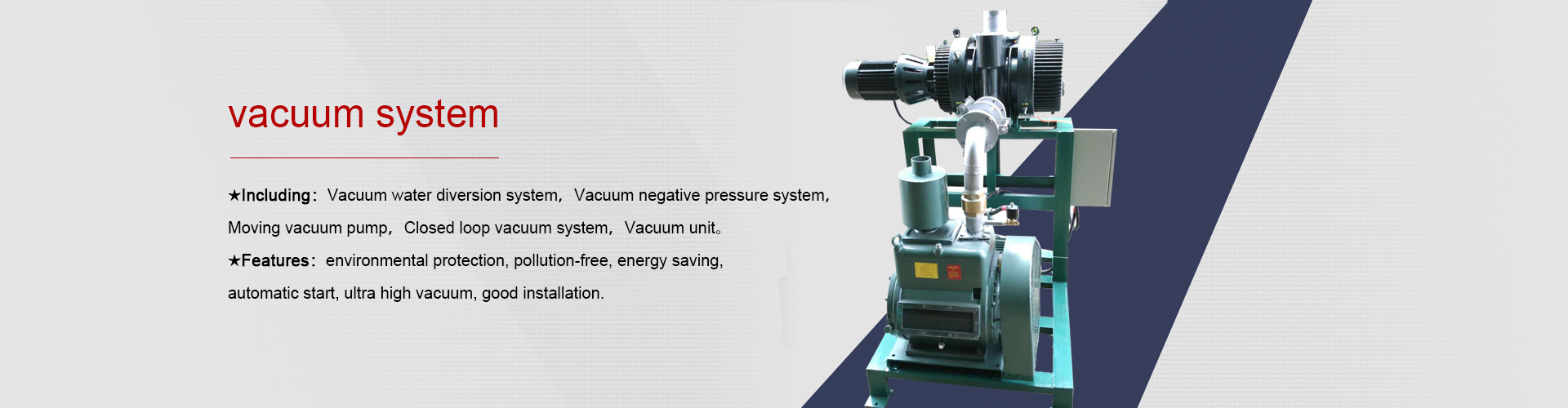

Features: no lampblack, no pollution, high vacuum, ready to use, automatic control, stable performance.

Application Industry: electrician, textile, CNC engraving machine, vacuum forming machine, folding machine, light breaker, computer, semiconductor application, circuit board, battery, capacitor, binding machine, photographic plate machine, freeze-air conditioning vacuum, packaging machine, transformer, optical lens, automatic injection molding, polyurethane technology, label paste machine, Printing press, circuit board machine vacuum elevator, vacuum sucker, printing machine, VCD&DVD surface vacuum splash plating, industrial furnace, smelting and heat treatment, metal vacuum coating, vacuum welding, electron beam welding, vacuum coating, vacuum dry welding, vacuum packaging industry, space simulation, scientific research field, hospital negative pressure system, environmental protection Industries such as industry, electronics industry, laboratory, plastic industry, general machinery, glass, marble, heavy metal and heavy vacuum handling.

дёҖпјҡVacuum water diversion system

JMXT vacuum water diversion system is a new generation of The water pump, Vacuum water diversion product with simple structure, mature application and reasonable configuration.It is widely used in the vacuum water diversion of large pumps before mining, such as waterworks, power plants, paper mills and petrochemical industries. The traditional structure form of the bottom valve in the intake pipe of the suction pipe is completely replaced when the water pump is filled in, which can reduce the loss of the suction pipe and improve the suction performance of the pump.

JMXT Vacuum drainage system. Used in the pump room, pumping station, sewage treatment, such as vacuum water diversion and the design and manufacture of special occasionsгҖӮThis device is used for The water pump in The water pump station to automatically fill The water, so that all The water pump is always in a water filling state, and any one of The water pump can be started at any time.With this device, the ground pump station can realize automation operation, and can get rid of the design of the traditional semi-underground self-filling water pump station.гҖӮSo can save a lot of pumping station construction costs, to avoid the Water pump flooded the possibility of improving the Water pump working conditions and the operating environment, to ensure that the Water safety Water supply pump station, the device is good airtight performance, high degree of automation, convenient operation, safe and reliable work.

дәҢпјҡVacuum water diversion system Working principle

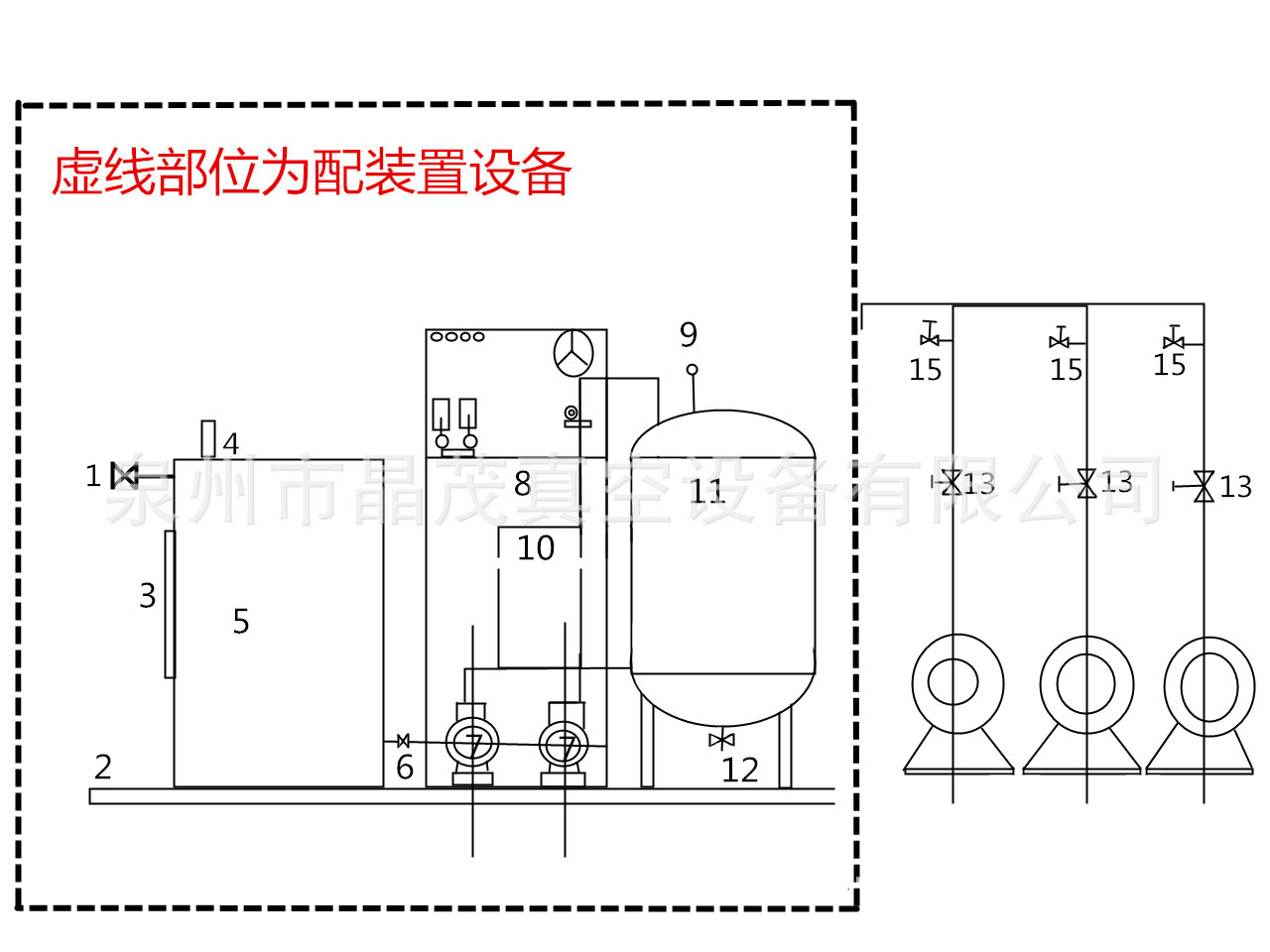

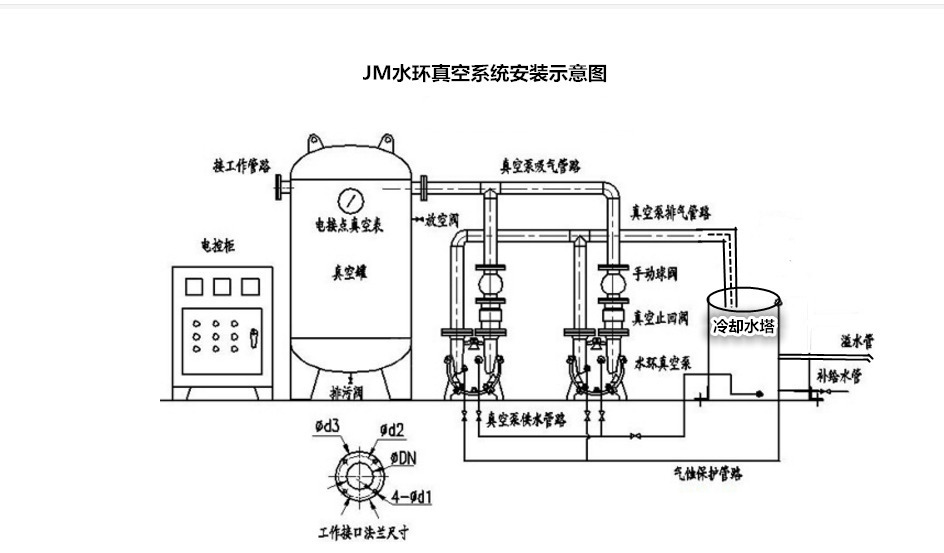

The vacuum drainage system consists of two JBV water ring vacuum pumps, a vacuum tank, a circulating water supply tank, a set of pipeline valves and a set of electrical automatic control distribution boxesпјҢWith vacuum tank as the vacuum equipment package system, vacuum pumping station in all Water pump are installed at the top of the vent one-way valve (is beyond the scope of distribution device, need further preparation) are connected to the vacuum storage tanks and pipes.The one-way valve is used to make the air in the pump freely enter the vacuum box, and the water can not pass through the check valve.The opening and stopping of the centrifugal pump is controlled by the central controller through the solenoid valve and the flow switch on the vacuum pipeline, and the electromagnetic valve is normally closed.пјҢThe central controller needs to start the centrifugal pumpпјҢFirst open the solenoid valve and start the centrifugal pump at the same timeпјҢThe vacuum tank is equipped with an automatic signal generator.Vacuum equipment works automatically according to instructionгҖӮWhen the vacuum degree of the vacuum system is lower than the lower limitпјҢPrompt stop instruction vacuum device to stop automatically.The working fluid can be recycledпјҢThe system greatly reduces the consumption of working fluids and environmental pollution.So the suction gas is poisonousпјҢIt has obvious advantages in various occasions such as removing gas containing organic solvents.пјҢWater is used as the medium in the working fluid in this system.

дёүпјҡProduct characteristics of vacuum system

1. High vacuum degree, stable performance and long life.

2. flow: 4-1300m3/hr (single pump)

3. vacuum usage: 0.5-500mbar (absolute pressure)

4. there is no need to access the water source

5. Compact structure, covering an area of small.

6. Easy maintenance and low noise.

7. PLC control of multiple units can be realized.

8. Connect to GDMS system.

еӣӣпјҡWorking principle of vacuum systemпјҡ

First set the upper and lower limits of the vacuum systemпјҲFor example, the upper limit is set to -0.08MPa, and the lower limit is set to -0.06MPa.),After starting the systemпјҢOne of the vacuum pumps began to work.пјҢThe vacuum degree in the vacuum tank is higher than the upper limit of -0.08MPaпјҢThe vacuum pump will stop running automatically at this timeпјҢThe vacuum in the vacuum tank is automatically cut off from the vacuum check valveпјҢIf the working requirements are met, the vacuum degree in the vacuum tank can be reduced to -0.06MPa below the lower limit.пјҢAnother vacuum pump starts automatically until the vacuum level reaches a maximum value over a certain time.пјҢAnd a single vacuum pump can not reduce the vacuum in the tank above the lower limit.пјҢAnother vacuum pump will automatically start until the upper limit is exceeded.

дә”пјҡVacuum water diversion systemй…ҚзҪ®пјҡ

Follow the official WeChat

Follow the official WeChat