products

Contacts: Li Sheng

Telephoneпјҡ18150992829

Faxпјҡ0595-88056969

Address: Jinjiang Cizao Fujian city of Quanzhou Province east slope money 205205

products

Contact us

|

2, dust removal hood (user selection): prevent sawdust and other debris into the pump.

3. Check valve; Downtime, prevent the water back into the vacuum mesa inside the pump.

4. Inlet pipe; Towards the vacuum pump to inject working fluid (water), the equipment produces a vacuum.

5. The intake valve controls the amount of working fluid. Before opening the machine, the valve must be fully opened and the water must be entered into the pump before starting the vacuum pump.

6. Drain port; In the equipment use 10 days or so, drain the working fluid in the water tank, replace the clean water.

7. Exhaust port; Produced in the process of adsorption of gases, the atmosphere through the vent port, vent can not be blocked, can not install Exceed two meters of the Piping, can't take less than 5 cm in diameter pipe. Otherwise easy to overload and damage the motor.

8. Upper water level; Add water to the water tank until the upper water level reaches the water level, and add water regularly before starting the vacuum pump every day to ensure sufficient working fluid in the tank.

9, water tank; work liquid.

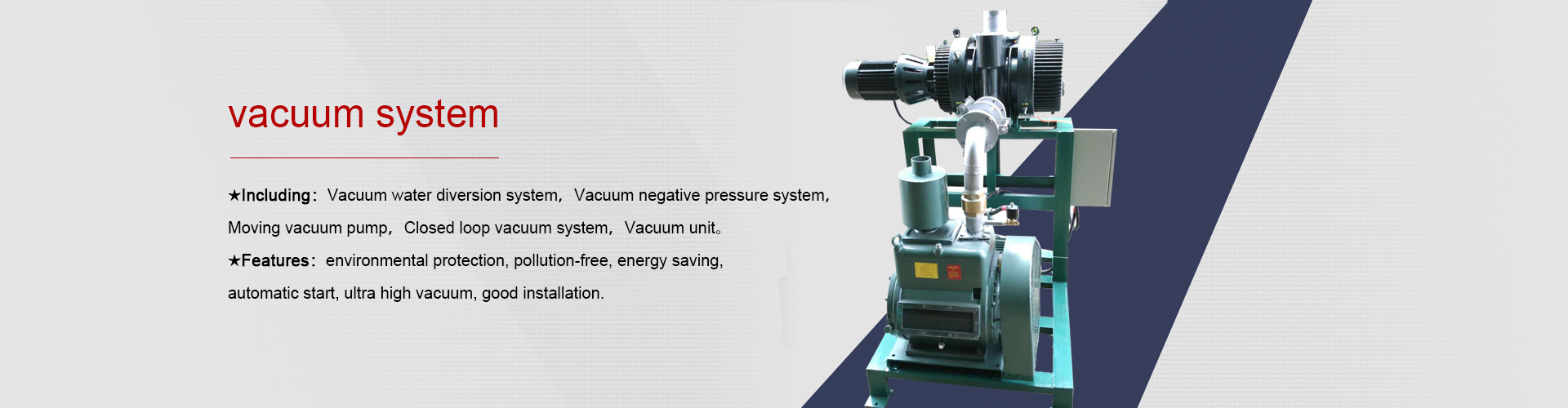

Engraving machine vacuum pump is our company's requirements for woodcarving numerical control engraving.Combined with the comprehensive parameters of the water ring vacuum pump and the actual situation of NC engraving.Specialties are used for woodworking adsorption, glass adsorption, metal adsorption and so on, which require vacuum adsorption, vacuum traction, vacuum hoisting, real space rest feed, a set of Vacuum negative pressure device.гҖӮ

The vacuum pump of the engraving machine has the main negative pressure power source water ring vacuum pump, the vacuum check valve, the silencer, the solenoid valve, the air switch, the filter, the water bath dust tank (the user selected), the circulating water tank, the pipe and the valve and so onгҖӮ

дёҖгҖҒCharacteristics of vacuum pump for engraving machineпјҡ

The vacuum pump for engraving machine is widely used for vacuum adsorption of thin and smooth metal products, glass, paper, density board, plank, plexiglass and PVC board. It can also be used for vacuum casting of gold and silver jewelry, temperature impregnation, and aluminum alloy grain printing.

1, suction port; connect woodworking engraving machine adsorption pipe, outer diameter 47mm.

2, dust removal hood (user selection): prevent sawdust and other debris into the pump.

3. Check valve; Downtime, prevent the water back into the vacuum mesa inside the pump.

4. Inlet pipe; Towards the vacuum pump to inject working fluid (water), the equipment produces a vacuum.

5. The intake valve controls the amount of working fluid. Before opening the machine, the valve must be fully opened and the water must be entered into the pump before starting the vacuum pump.

6. Drain port; In the equipment use 10 days or so, drain the working fluid in the water tank, replace the clean water.

7. Exhaust port; Produced in the process of adsorption of gases, the atmosphere through the vent port, vent can not be blocked, can not install Exceed two meters of the Piping, can't take less than 5 cm in diameter pipe. Otherwise easy to overload and damage the motor.

8. Upper water level; Add water to the water tank until the upper water level reaches the water level, and add water regularly before starting the vacuum pump every day to ensure sufficient working fluid in the tank.

9, water tank; work liquid.

дәҢгҖҒUse of vacuum pump for engraving machineпјҡ

1, the suction mouth and engraving machine adsorption pipeline connection, strictly seal, prevent leakage.

2. For the first time, use a screwdriver to push the motor fan to ensure that the impeller is not stuck.

3. Connect the power of the motor and adjust the running direction to match the mark.

4. Fill the tank with water until the upper water level is overflowing.

5. Open the water injection valve inside the vacuum pump and wait for three minutes to ensure that the working fluid flows into the pump.

6. Start the motor, the vacuum pump starts to work, and the adsorption surface is adsorbed.

еӣӣгҖҒMain technology of vacuum pump for engraving machineпјҡ

| еһӢеҸ·model |

жҠҪйҖҹ(m3/min )Pumping speed |

еҠҹзҺҮ(KW)

power |

еӨ§зңҹз©әеәҰ(Mpa)

vacuum degree |

еӨ§еҗёйҷ„йқўз§Ҝ(m2)

Adsorption area |

| JMSX-2070 | 1.3 | 3 | -0.098 | |

| JMSX-5110 | 2.7 | 4 | -0.098 | |

| JMSX-5111 | 3.8 | 5.5 | -0.098 | |

| JMSX-5121 | 4.6 | 7.5 | -0.098 | |

| JMSX-5131 | 6.6 | 11 | -0.098 | |

| JMSX-5161 | 8.3 | 15 | -0.098 |

Follow the official WeChat

Follow the official WeChat