products

Contacts: Li Sheng

Telephoneпјҡ18150992829

Faxпјҡ0595-88056969

Address: Jinjiang Cizao Fujian city of Quanzhou Province east slope money 205205

products

Contact us

|

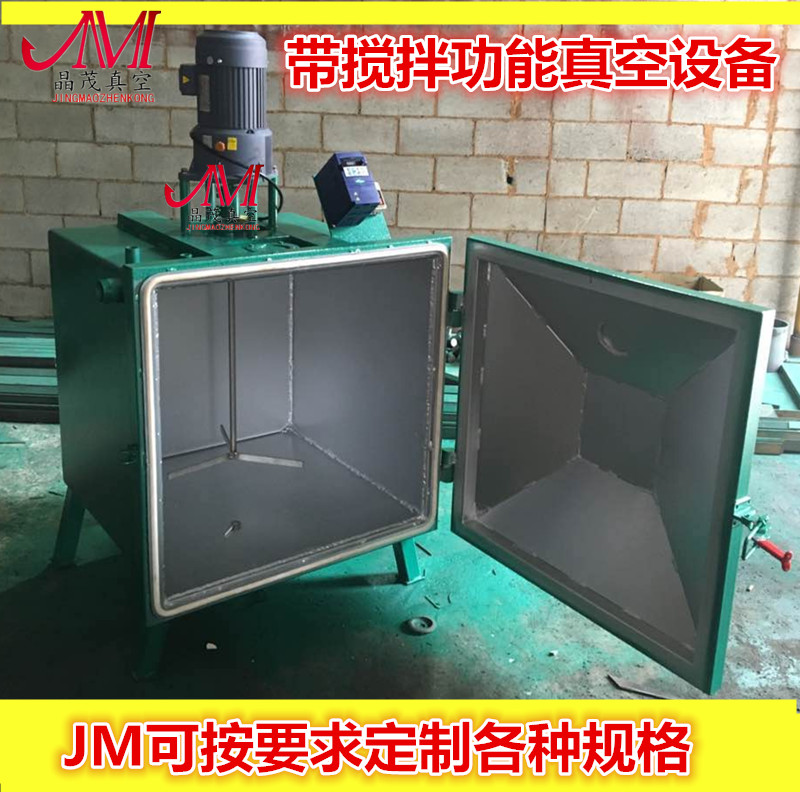

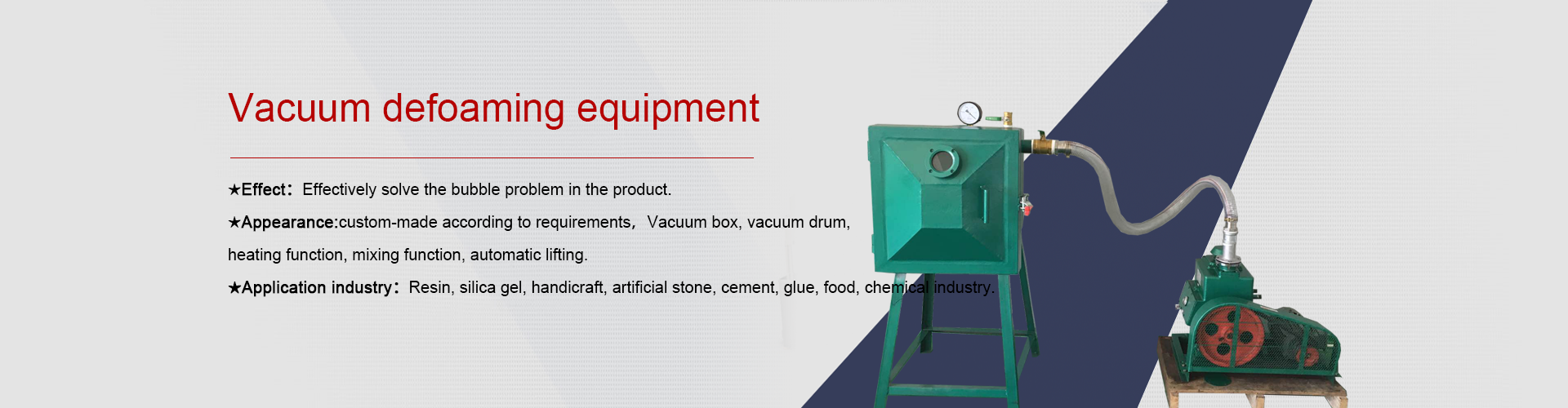

дёҖпјҡ Vacuum mixer Effect

гҖӮSolve the problem that the traditional mixing equipment can't solve. The slurry and powder of different components are fully mixed evenly, no stratification, no bubbles, and high efficiency. The vacuum time is 1-30 minutes at one time. Meet the requirements of mixing process to high qualityдәҢпјҡVacuum mixerеә”з”Ё

It is mainly used in the mixing fields of LED, LCD, medical devices, electronic components, nano powder materials, fine chemical materials, printed electronic materials, electronic packaging materials and new energy materials, such as high, sharp and fine materials, such as fluorescent powder, silica gel, silver pulp, aluminum slurry, adhesive, ink, silver nanoparticles. Grain, silver nanowire, LED/OLED/SMD/COB conductive silver glue, insulating adhesive, RFID printing conductive ink and anisotropic conductive adhesive ACP, conductive paste for thin film solar cells, conductive ink for PCB/FPC, etc., from liquid to solid, liquid and liquid, solid and solid material.дёүпјҡVacuum mixerйҖүиҙӯж–№ејҸ

1.concentrationпјҡDifferent concentration, its preparation is different. Please explain it clearly. Different prices are different.

2.Vacuuming timeпјҡIf there is any restriction on the vacuum defoaming time, please let us know in advance.

3.yieldпјҡSome users directly put the mold to vacuum, which needs to provide mold size, and need to put several molds into the box.If the raw material of the product is directly vacuoled, it is necessary to provide the weight of the product to customize the size.

4.parameterпјҡEach device can go to -0.1mpaпјҢTo -0.1mpa, and to remove bubbles is not an idea. Different products can solve the bubble problem in the product with different equipment.

еӣӣпјҡVacuum mixer parameter

The following table is only a few common specifications. If it is not suitable for production according to the requirements, the preparation is only recommended and can be prepared according to practical application.

|

еһӢеҸ· Model |

и®ҫеӨҮй…ҚзҪ®Equipment configuration |

еҠҹзҺҮMotor rated powerпјҲKWпјү |

|

|

е°әеҜёsize

Wide, high, deep |

зңҹз©әжіө Vacuum pump |

||

|

JM-300 |

300Г—300Г—300 |

J2X-4/ J2X-8 |

0.55/1.1 |

|

JM-400 |

400Г—400Г—400 |

J2X-8/ J2X-15 |

1.1/2.2 |

|

JM-500 |

500Г—500Г—450 |

J2X-15/ J2X-30 |

3/5.5 |

|

JM-600 |

600Г—600Г—500 |

J2X-30/ J2X-70 |

3/5.5 |

|

JM-700 |

700Г—600Г—600 |

J2X-70/ JX100 |

5.5/7.5 |

|

JM-800 |

800Г—700Г—500 |

J2X-70/ JX-100 |

5.5/7.5 |

|

JM-900 |

900Г—800Г—600 |

J2X-70/ JX-100/H150 |

5.5/7.5/15 |

|

All sizes can be produced. |

|||

еӣӣпјҡInstallation operation description of vacuum defoaming machine

1. the equipment includes accessories, box, vacuum pump, pipe, valve, relief valve, vacuum gauge, lock catch and flange.

2. the first step is to place the vacuum pump and vacuum box neatly, and put them in the place where the power supply and operation are convenient.

3. The Air suction valve, vacuum gauge, Pressure relief valve and reserved pipe with Adhesive tape wrapped tightly screwed up, need to use a lot of tape to avoid leakage, such as with flange of the flange is installed on the vacuum pump suction mouth, please.

4. take out the plastic pipe andLock catch, the end of the interface wrapping tape, one end installed on the box, one end installed on the vacuum pump, remember the two ends to tighten, otherwise the air leakage, the vacuum table will not reach -0.1MPA.

5. Install Pressure relief valve. Normal Pressure relief valve is designed at the top. The caliber USES raw tape to tighten and tighten the Pressure relief valve.

6. Install the vacuum gauge, and the operation method is the same, tighten the caliber with Raw tape and install the vacuum gauge at the top.

7.15l vacuum pump and the following extraction rate are air-cooled, 30L vacuum pump and above pumping speed are water-cooled, and need to be cooled by Water, with Water pump.

8. there are two observation windows on the vacuum box. The observation window at the top is used for lighting, and the front observation window is used to observe the internal foam removal.

9. installation of power supply

дә”пјҡVacuum mixerе®һжӢҚеӣҫ

Follow the official WeChat

Follow the official WeChat