products

Contacts: Li Sheng

Telephoneпјҡ18150992829

Faxпјҡ0595-88056969

Address: Jinjiang Cizao Fujian city of Quanzhou Province east slope money 205205

products

Contact us

|

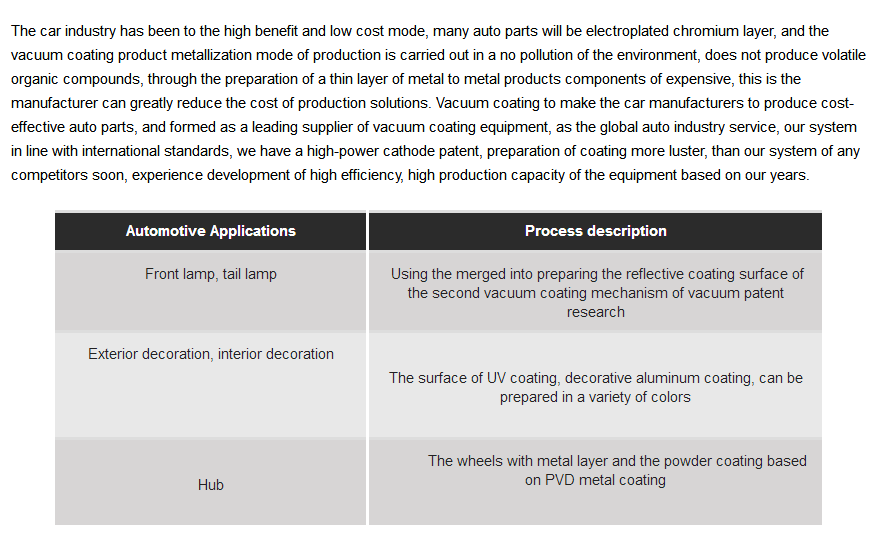

Car Wheel hub

Automative lighting

Rearview mirror

Engine

Car body, etc.

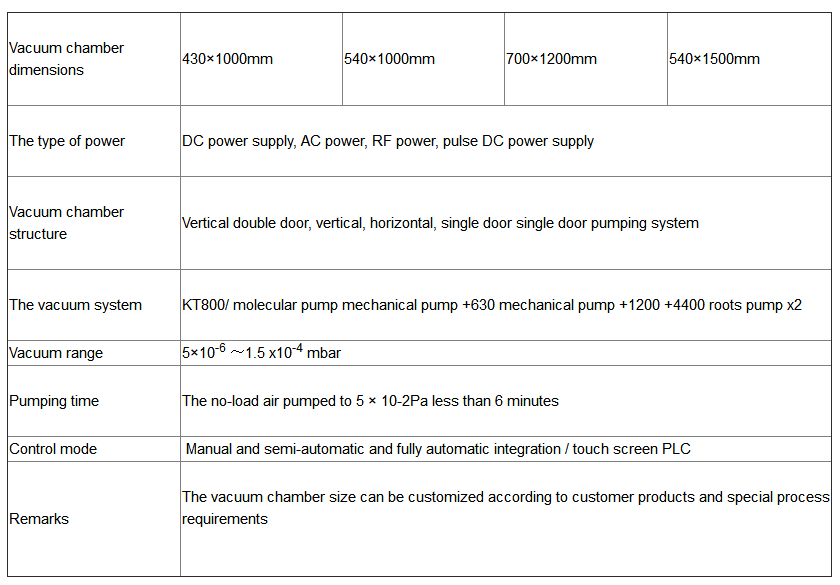

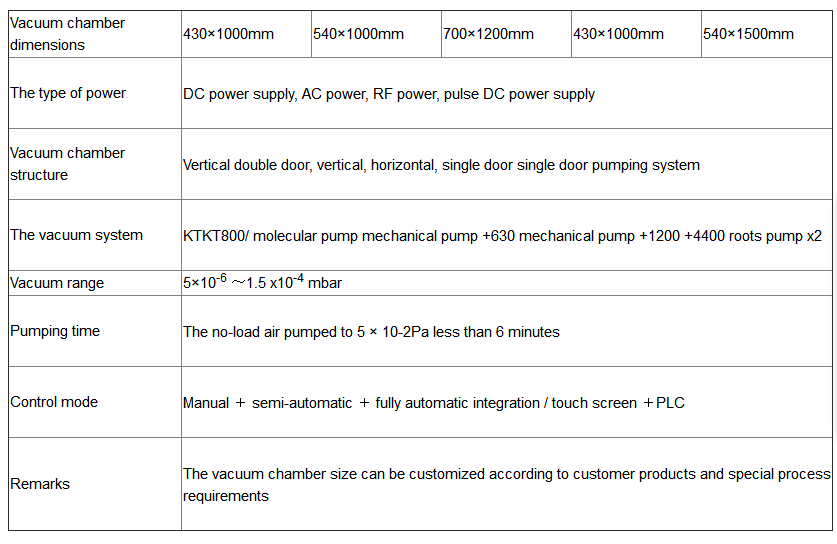

дёҖпјҡAuto parts vacuum coating machine.

Widely used in aluminum alloy automotive wheel plating: titanium, chromium, zirconium, stainless steel, silver, copper, aluminum and other composite metal coatings. The technical personnel of the company are unremitting efforts to focus on the research and development of physical vapor deposition technology, and through the special magnetron sputtering system, the computer automatic control system is adopted. Widely used in automobile parts plating: titanium, chromium, zirconium, stainless steel, silver, copper, aluminum and other composite metal coatings.

дәҢAuto parts vacuum coating machine

2: high gloss degree: the protective film effect is bright.

3: high wear resistance: the protective film has 6H super high strength and good abrasion resistance.

4: super durability: under normal use and maintenance, car paint protection for more than 2 years.

5: is clean and convenient: it has super strong self-cleaning property and is not easy to stick dust and dirt, such as acid rain, bird droppings, etc.

6. Super environmental protection: use all environmental materials, do not oxidize themselves, and do not cause secondary pollution to car paint.

дёүпјҡAuto parts vacuum coating machine.дёӢй…ҚеҲ¶

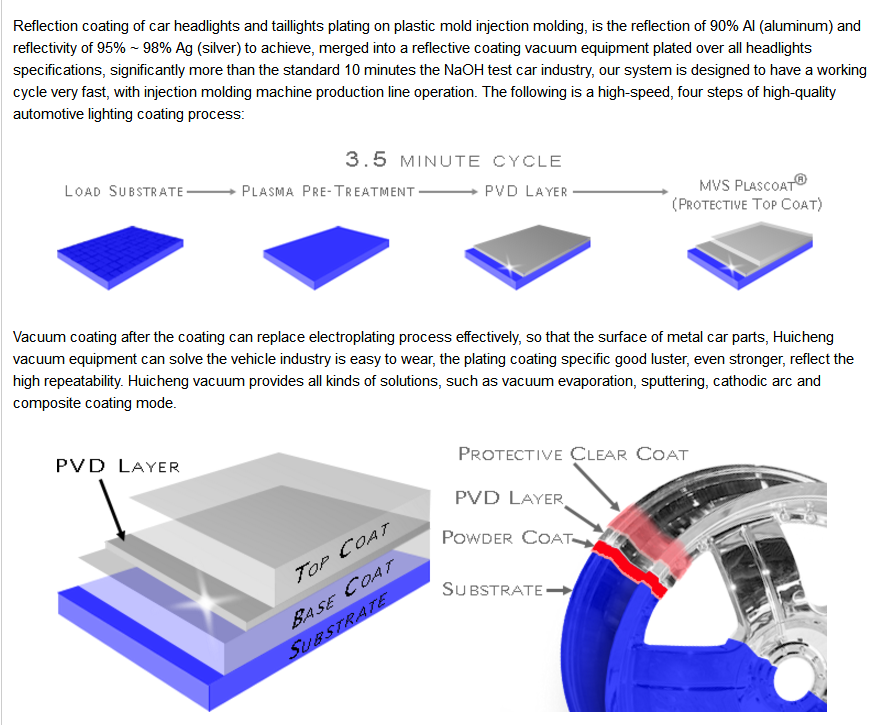

1.Automobile lighting vacuum coating machine.

Car lamp reflective film, reflective cup, front lamp, rear lamp, turn signal, license plate lamp, etc.

The former headlights include halogen tungsten lamp, xenon lamp, near-light bulb, high beam, front turn signal, front lamp, front fog lamp, rear headlamp, rear lamp, brake lamp, rear fog lamp, rear turn signal.

2.Automobile hub vacuum coating machine:

It is not tightly coated with only wheel hub, including gas front headlights, taillights, doorknobs, rear view mirrors, pistons, piston rings, alloy wheels, engine parts, synchronizer components, pumps and so on.

3.Automotive steel plate zinc magnesium coating equipment.

The surface coating of the galvanized steel plate coated with zinc and magnesium alloy is more compactness, binding force, corrosion resistance and processability. The commonly used protective coating is a pure zinc coating.With the development of science and technology, the superiority of zinc magnesium alloy coating is more obvious. Magnesium is a kind of metal material with light and beautiful quality. It has good thermal conductivity, machinability and zinc magnesium alloy with high strength, light weight and strong corrosion resistance.It is one of the better anticorrosive coatings in the zinc base, and the anticorrosion performance is 23 times higher than that of pure zinc coated steel plate, and it is well received by the automobile industry.The main current technology of zinc magnesium alloy coating is obtained by the technique of evaporation or electron beam evaporation of vacuum evaporation coating machine. It has high film forming rate, and the film is prepared between several microns and dozens of microns.

Follow the official WeChat

Follow the official WeChat