products

Contacts: Li Sheng

Telephoneпјҡ18150992829

Faxпјҡ0595-88056969

Address: Jinjiang Cizao Fujian city of Quanzhou Province east slope money 205205

products

Contact us

|

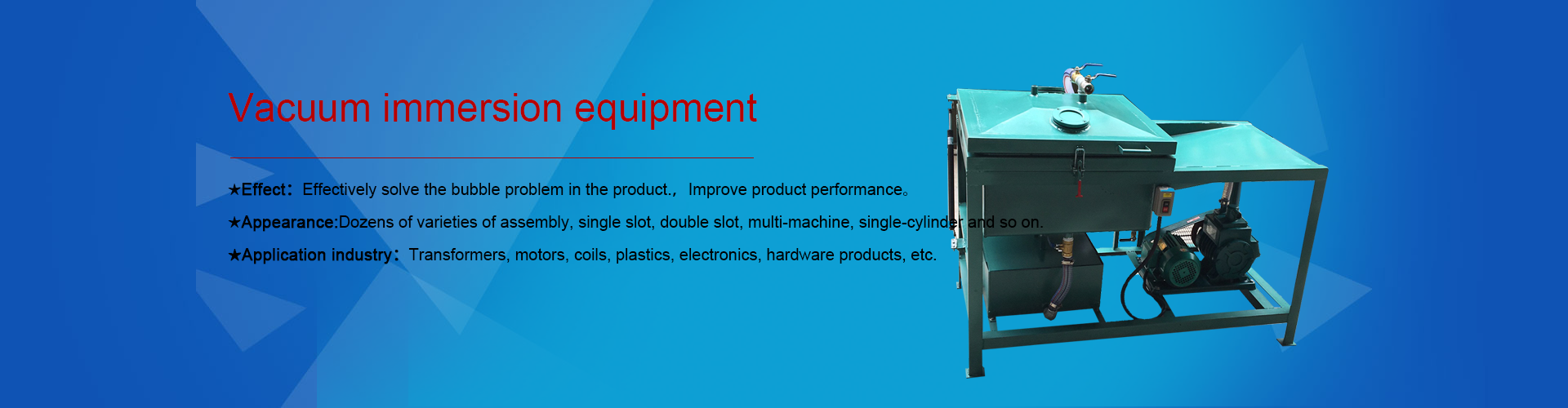

Single cylinder structure

Double groove structure

Fully automatic

Split structure

Conjoined structure

Appearance can be designed, square, round

Materials are: carbon steel material and stainless steel material

дёҖпјҡVacuum impregnating machine introduce

Tailor made

Single cylinder structure

Double groove structure

Fully automatic

Split structure

Conjoined structure

Appearance can be designed, square, round

Materials are: carbon steel material and stainless steel material

дәҢпјҡVacuum impregnating machine application

Vacuum dipping machine is a suitable for high frequency and low frequency transformers, inductors, inductance coil, motor, rectifier, metal castings and C type iron core varnished processing equipment, improve the mechanical strength of wire coil, dielectric strength and moistureproof, mouldproof, reduce noise, and other functions; The vacuum degassing process of various metal film capacitors, electrolytic capacitors, medium/small resin handicrafts, and all kinds of plastic PU raw materials vacuum degassing process. It can improve product quality, reduce production cost, save efficiency and protect environment. The equipment is general assembly, bulk type, square cylinder type, single machine multi-cylinder type, multi-machine single cylinder type and multi-machine multi-cylinder type and dozens of varieties. The principle is to place the workpiece in a vacuum vessel, remove the water and air and other volatile matter in the workpiece by vacuuming, and then fill the gap with insulating material. It can improve the penetration ability of insulating paint and increase the filling rate, so as to improve the overall mechanical strength, insulation strength, moisture resistance and mildew resistance of electrical coil.

дёүпјҡVacuum impregnating machine

1.Size: do not design too high unless the product is large.

2Parameter: customized according to the time requirement,

еӣӣпјҡVacuum impregnating machine The working principle of

1гҖҒPut the impregnated object into the cylinder, close the cylinder head and lock the cylinder locking device.

2гҖҒVacuum pressure is maintained for a period of time, and the liquid in the liquid storage tank is pushed into the cylinder under the action of the atmosphere. After the liquid reaches a certain height, the liquid inlet pipe is closed.

3гҖҒ(continue) vacuuming: maintain after a certain negative pressure.

4гҖҒBalance (inhalation), open the suction nozzle, and the air will naturally enter the cylinder under the action of atmospheric pressure, so that the pressure inside the cylinder is equal to the external pressure of the cylinder body.

5гҖҒThe liquid is dipped into the raw material by vacuuming. (basically, the liquid inside the cylinder enters the object. To make the cylinder body immersed in a balanced or impregnated body.

6гҖҒExhaust (exhaling and emptying) and open (suck) the vent to exhalate the air in the container. The pressure is equal to the outside of the container.

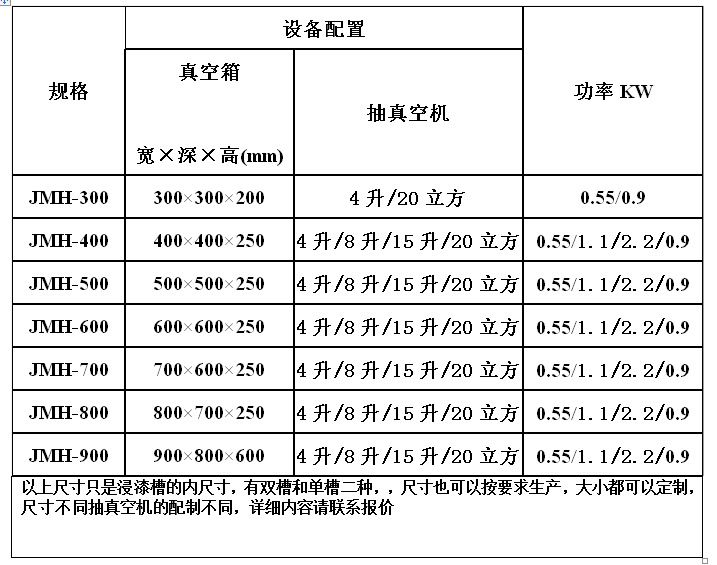

дә”пјҡVacuum impregnating machine Size table

дә”пјҡзңҹз©әеҗ«жөёжңәе®һжӢҚеӣҫ

Follow the official WeChat

Follow the official WeChat