products

Contacts: Li Sheng

Telephoneпјҡ18150992829

Faxпјҡ0595-88056969

Address: Jinjiang Cizao Fujian city of Quanzhou Province east slope money 205205

products

Contact us

|

Super hard tool coating equipment can be applied to the drill, taps, high speed blades, wear-resistant bearings and other functional coating, which can greatly improve the service life and use efficiency of the product.

Commonly used membrane systems include TiN, ZrN, TiAlN, TiC, TiCN, CrN, Al2O3, etc.

Performance of multi arc ion vacuum coating machine

Multi arc ion plating equipment has high deposition rate, high ionization rate, high ion energy, good adhesion of film layer, simple operation of equipment, low operation cost and high production efficiency. The hard coating with micron thickness can effectively protect the appearance of the plated product. Low temperature coating process can be deposited on various materials, and various combinations of coating processes can create more colors.

еӨҡеј§зҰ»еӯҗзңҹз©әй•ҖиҶңжңәеә”з”Ёпјҡ

The multi arc ion vacuum coating machine can be coated on the surface of metal, glass, ceramics and other materials. Ordinary decorative coating equipment is widely used in stainless steel exhibits, stainless steel pieces, door flowers, flower sprinklers, handles, water heating hardware, clocks, sanitary ware, tableware, faucets, metal hullers, metal shells of mobile phones, glass crystal ornaments, glass tubes, etc.

гҖҖгҖҖSuper hard tool coating equipment can be applied to the drill, taps, high speed blades, wear-resistant bearings and other functional coating, which can greatly improve the service life and use efficiency of the product.

гҖҖгҖҖCommonly used membrane systems include TiN, ZrN, TiAlN, TiC, TiCN, CrN, Al2O3, etc.

Characteristics of multi arc ion vacuum coating machine

1.Metal decoration ion vacuum coating

This equipment is an efficient and non polluting ion plating equipment. It has the characteristics of fast deposition rate, high ionization rate, high ion energy, simple operation of equipment, low cost and large production capacity.

The principle of the vacuum arc ion plating is based on the cold cathode self holding fox light discharge plasma evaporation, the ionization plating, combined with the pulse bias technology, to improve the energy and activity of the deposited particles and enhance the properties of the film. It is not only coated on the surface of the metal products, but also can be coated on the surface of the nonmetal products.It can be coated with metal film, titanium nitride, titanium carbide, zirconium nitride, chromium nitride and nickel, chromium, copper and other compound films, multilayer superdura and titanium nitride film, etc. the arc ion coating is widely used in tools, superhard coatings, automobile wheels, golf tools, clocks, hotel supplies, sanitary ware, lamps. Glasses frames, hardware, ceramics and glass.

2.Magnetic brick vacuum coating machine.

After the ceramic tile vacuum coating equipment processing, the ceramic tile is more luster and the wear-resisting index is greatly improved. It can produce the imitation gold, the rose gold, the silver white, the black and so on.

Ceramic tile vacuum coating equipment is mainly used for ceramic tile, ceramic tile and ceramic tile plasma coating. The equipment is equipped with cathode arc steam source, also with bias voltage power supply and magnetron sputtering target. The main feature is strong pumping system, fast pumping, high loading capacity, high production capacity, low production cost, and can produce imitation gold and rose. Gold, silver white, black and other layers: the color pattern pattern can be obtained by using the applique paper and the coated water soluble shielding technology. The tiles after the vacuum coating of ceramic tiles are more lustrous and the wear-resistant index is greatly improved.

Applications: ceramic tiles, porcelain tiles, ceramic tiles, plasma coating. Tile floor, building tile, art tile industry, suitable for production of brick, wall tiles, porcelain, waist line, mosaic, decoration, mosaic, tiles and other electroplating coatings.

3.Mosaic vacuum coating machine

Features: large capacity, high production capacity, low production cost, can be plated with imitation gold, rose gold, coffee color, bronze color, blue, fantasy color and so on, mosaic gold and rose gold after the mosaic.

Silver plated mosaic after chromium plating

The mosaic vacuum coating machine is mainly used to produce color, glossy mosaic plasma plated color film. The equipment is equipped with cathode arc evaporation source, also with bias voltage power supply and ion bombardment. This load is large, high production capacity, low production cost, and can produce imitation gold, rose gold, coffee color, and ancient times. Copper, blue, phantom color, etc.

Three dimensional rotary mechanism can be provided to make the color more uniform. After mosaic, titanium is made into gold and rose gold.

Silver plated mosaic after chromium plating

4.Daily ceramic vacuum coating machine.

The vacuum coating machine is mainly used for ceramic tiles, porcelain, daily ceramic products (such as tableware, stationery), process ceramics (vases, characters, ornamental ornaments) plasma coating, the equipment is configured as cathode arc steam source, also with bias power supply, also with magnetron sputtering target.

Features: it can produce gold imitation, rose gold, silver white, black and other films: decal paper and coated water.The colored shield pattern can be obtained by the technology of soluble shielding, and the tiles are more glossy and the wear-resistance index is greatly improved after vacuum plating.

5.Continuous ceramic vacuum coating production line

It is mainly used for ceramic tile, ceramic tile, ceramic tile plasma plating film, and the production of Spanish technology, which can realize the automatic production line of baking and coating functions.

The cathode arc evaporation source also has bias voltage power supply and magnetron sputtering target.

With a powerful vacuum system, fast pumping, high loading, high production capacity, low production cost, it can produce imitation gold, rose gold, silver white, black and so on: applique paper and coating water

The colored shield pattern can be obtained by the technology of soluble shielding, and the tiles are more glossy and the wear-resistance index is greatly improved after vacuum plating.

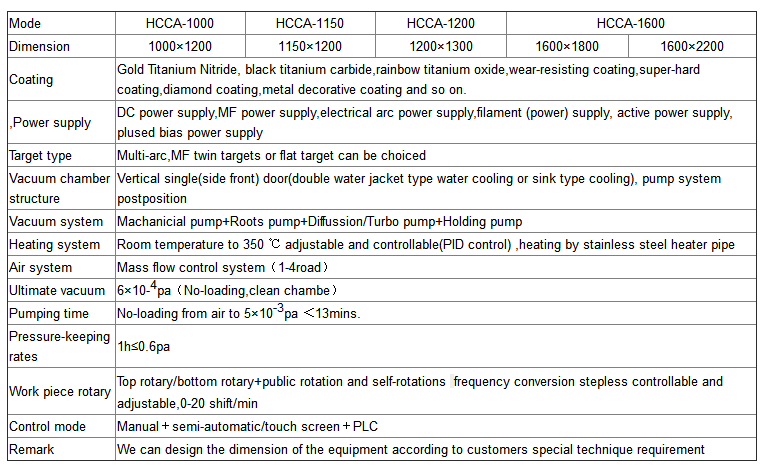

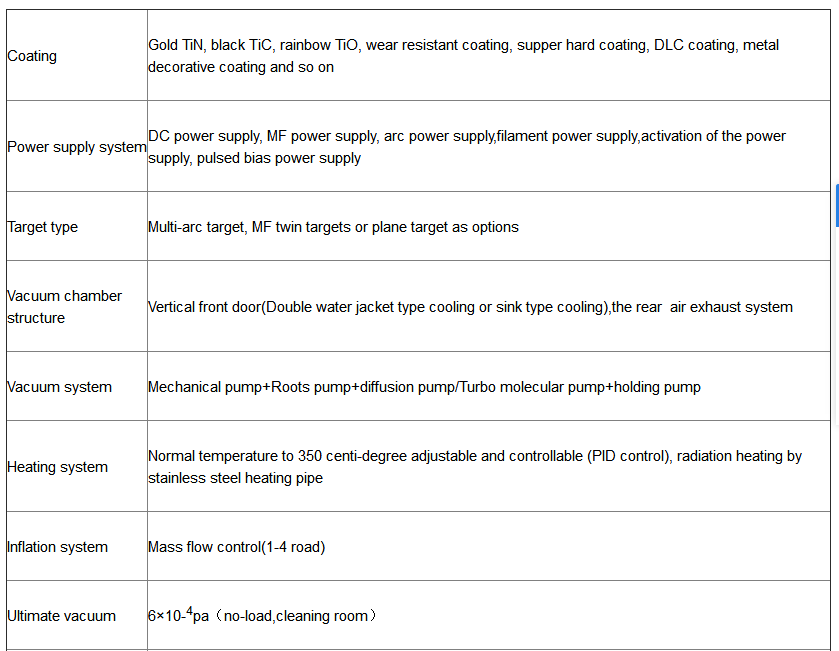

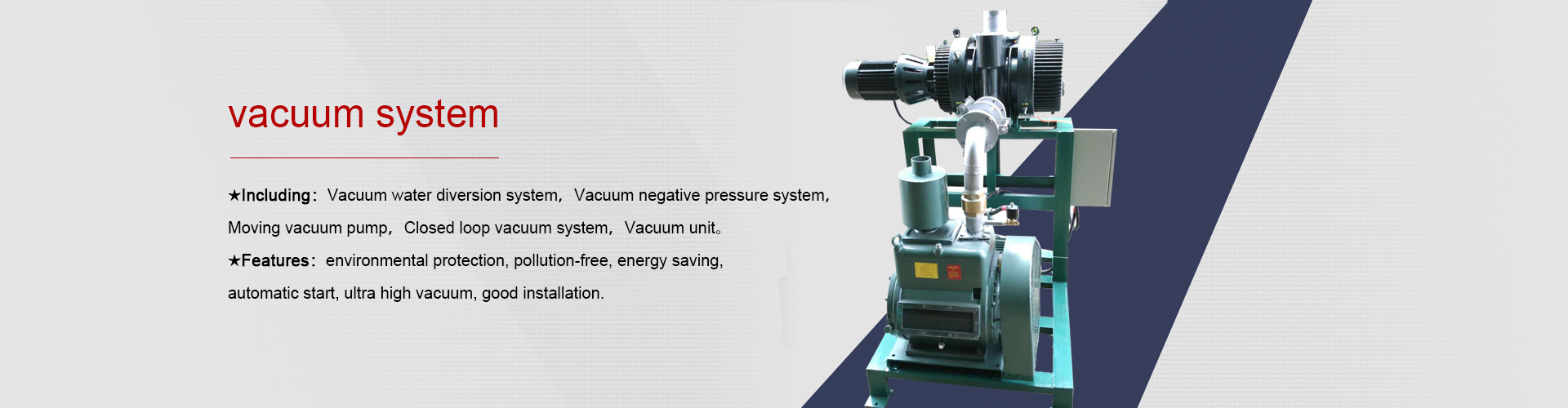

Technical parameters

Follow the official WeChat

Follow the official WeChat