products

Contacts: Li Sheng

Telephoneпјҡ18150992829

Faxпјҡ0595-88056969

Address: Jinjiang Cizao Fujian city of Quanzhou Province east slope money 205205

products

Contact us

|

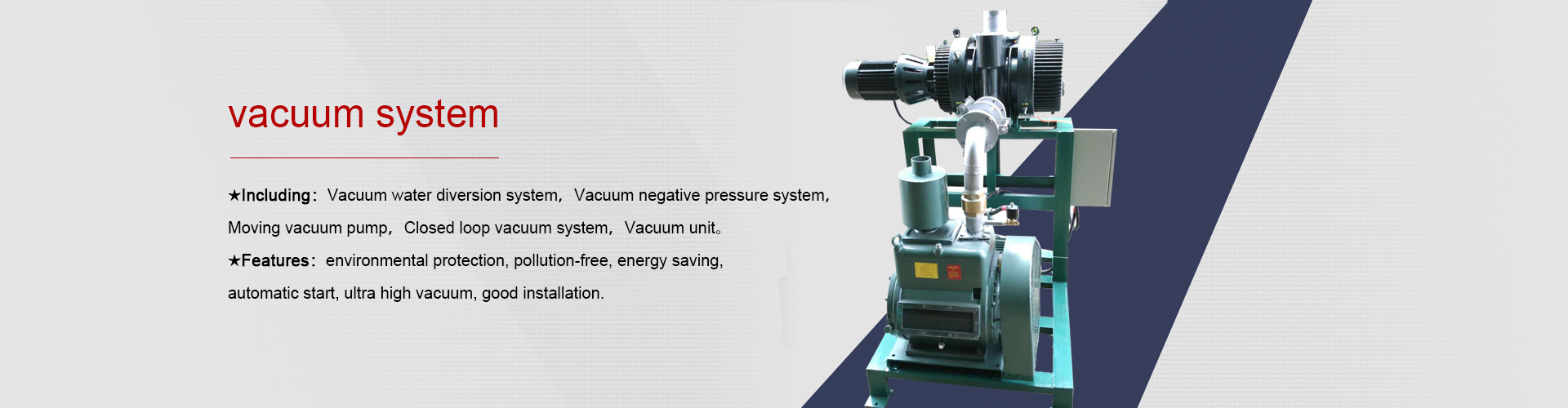

It can be used to prepare monolayer and multi-layer metal film, dielectric film, semiconductor film, magnetic film, sensor film and heat-resistant alloy film, hard film, corrosion resistant film, etc.

Example: silver, aluminum, copper, nickel, chromium, nickel-chromium alloy, titanium oxide, ITO, silicon dioxide, etc.

Single target sputtering, multiple target sputtering, common sputtering and other functions.

Size is customized according to production.

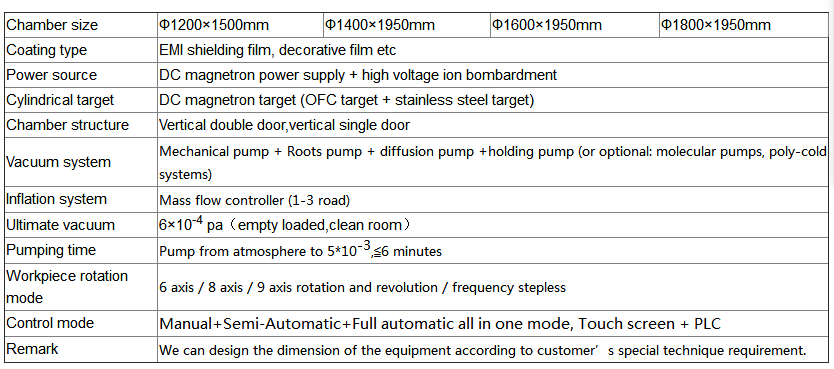

дёҖпјҡMagnetron sputtering vacuum coating machine

(1) various functional films: films with absorption, transmission, reflection, refraction, polarized light and so on. For example, low temperature deposition of silicon nitride antireflection film, in order to improve the photoelectric conversion efficiency of solar cells.

(2) the application of decoration field, such as various reflective film and semi-transparent film, such as cell phone case, mouse, etc.

(3) in the field of microelectronics, as a non thermal coating technology, it is mainly used in chemical vapor deposition (CVD) or metal organic.

(4) chemical vapor deposition (MOCVD) is difficult to grow and is not suitable for thin film deposition, and a large area of very uniform film can be obtained.

(5) in the optical field, the medium frequency closed field non-equilibrium magnetron sputtering technology has also been applied in the optical thin film (such as the antireflective film), the low radiation glass and the transparent conductive glass. In particular, transparent conductive glass is widely used in flat panel displays, solar cells, microwave and RF shielding devices and devices, sensors and so on.

(6) in the mechanical processing industry, the surface deposition technology of the surface functional films, the super dura mater and the self lubrication synovium have been greatly developed after being asked. It can effectively improve surface hardness, composite toughness, wear resistance and high temperature chemical stability, thereby greatly improving the service life of coating products.

Magnetron sputtering has played an important role in the research of high temperature superconducting thin films, ferroelectric thin films, giant magnetoresistance thin films, thin film luminescent materials, solar cells and memory alloy films.

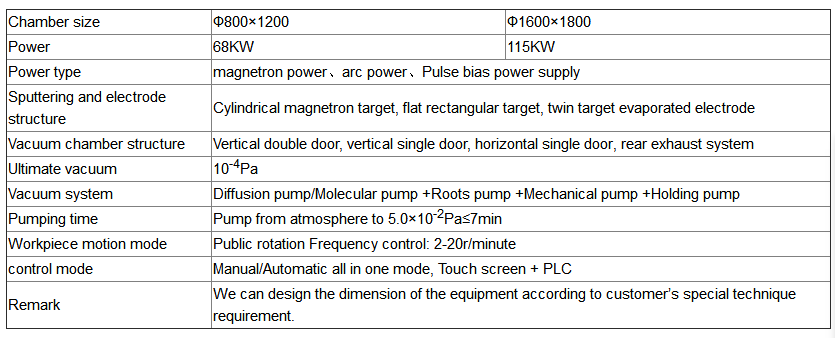

дәҢпјҡMagnetron sputtering vacuum coating machine

Using medium frequency sputtering plating hardware products to make it have higher added value, the product surface is more delicate and charming, the color is no sense of hierarchy, is the ideal surface decoration coating system. It is known as "decorative plating King machine".иҜҘThe equipment is mainly (set) DC magnetron sputtering, medium frequency sputtering and arc ion evaporation of three technologies, combined with line ionization source and stroke bias plating can make the sedimentary particles refined. The performance of the coating is improved, and alloy film, compound film and multilayer composite film can be plated on metal products and non-metal surfaces.After many years of research and development by the technical personnel of the company, a set of PROPOWER series computer automatic control system has been developed through the unique cathode arc ion and unbalanced magnetic control system, which can make the adhesion strength of the coating film strong and the conformance good and so on, which solves the complexity of manual manual operation and the color inconsistency of the film layer.It is widely applied to watch, jewelry puncture, mobile phone shell, home decoration hardware, sanitary ware, tableware and so on. Can be plated Tin, Tio, TiCN, CrN, TiALN, TiNbu, ZrN, TiNC and so on all kinds of performance of various colors.

1, the principle of magnetron sputtering is based on the theory of cathode glow discharge, which extends the magnetic field on the cathode surface to near the working surface and improves the ionization rate of sputtered atoms. It not only keeps the precision of magnetron sputtering, but also enhances the surface gloss.

2. The performance of the arc plasma vapour source is reliable. When the cathode and magnetic field coating is optimized, it can work under the 30A current. The coating film and the substrate interface produce the atom diffusion, and it has the characteristics of ion beam assisted deposition.

1.Medium frequency magnetron sputtering vacuum coating machine

Intermediate frequency magnetron sputtering technology has gradually become the mainstream technology of sputtering coating, and it is superior to DC magnetron sputtering coating.

It is characterized by overcoming the disappearance of the anode and reducing or eliminating the abnormal arc discharge of Sputtering target materials, thus improving the process stability of the sputtering process and increasing the deposition rate of the dielectric film several times.

The structure and layout of medium frequency sputtering target materials, such as flat target material, circular target material, target material and so on, are widely used in various decorative layers, such as TiN, TiC, TICN, TiAIN, CrN and so on, for the surface of the shell, the strap, the cell phone shell, the golf tool, the hardware, the tableware and so on.

2.Hardware jewelry vacuum coating machine.

Integrated with dc magnetron sputtering, intermediate frequency sputtering and arc ion evaporation technology, combined with the linear ionization source and pulse bias thin coating of sedimentary particles, to improve the performance of various membrane, can coat alloy film, multilayer composite membrane of metal

Surface is non-metallic, and through the unique cathodic arc and unbalanced magnetron ion system, we developed a set of computer automatic control make the coating adhesion density and complex good consistency and solve the complexity of manual operation, do not match the color film.

Hardware jewelry vacuum coating machine features: * the principle of magnetron sputtering is based on the theory of cathode glow discharge, expanding at the cathode surface magnetic field close to the surface, to increase the rate of sputtering atom ionization, it retains the magnetron sputtering is exquisite and glossiness increases

* the performance of the arc plasma vapour source is reliable. The structure coating of the cathode and magnetic field can be optimized according to the working current of 30A, and the interface of the coating and substrate is dispersed and the ion beam assisted deposition is added.

Application of vacuum coating machine for hardware jewelry: widely used in IPG clock, IPS watch and clock, IP of firearms, cell phone shell, hardware, sanitary ware, tool, friction proof tool, mould, it can make TiN, TiCN coating, nitriding TIALN, TiNbu, TiCrN, zirconium nitride, all kinds of diamond film (DLC)

3.Magnetron sputtering (EMI) special coating equipment.

Used in laptop computers, following, telephones, wireless communications, audio and video electronics, remote control, navigation and medical instruments, automatic control, configuration of high-power magnetron power source, double target used interchangeably,

Constant current output, the unique design artifacts, common rotation, high yield, high yield, using thick semiconductor vibration meter measuring film thickness, can accurate film thickness, plating machine interface of PLC automatic control system, at any time to modify the coating parameters

4Magnetron sputtering/vacuum evaporation composite coating equipment.

4Magnetron sputtering/vacuum evaporation composite coating equipment.

The magnetron sputtering / vacuum evaporation composite coating equipment combines magnetic control technology with vacuum evaporation technology in the same vacuum coating equipment. It uses magnetron sputtering anti polarization glow discharge to spatter the target material atoms and part of ionization deposition on the substrate.,At the same time, the metal is melted and evaporated in vacuum by resistance heating, and then deposited on the substrate to form film, which increases the use and flexibility of the device.,The equipment is applied to the metallization of the surface of the cell phone,It is applied to deposition of non-conductive film and electromagnetic shielding film, magnetron sputtering / vacuum evaporation composite coating equipment.гҖӮThe main feature is that it matches the plasma treatment device, the high efficiency magnetron sputtering cathode and the resistance evaporation device. The deposition rate of the equipment is fast, the coating adhesion is good, the coating is fine and compact, the surface finish is high, and the uniformity of uniformity is good. The coating process is fully automated, the loading amount is large, the work is reliable, the qualified rate is high, and the production cost is low. Green environmental protection,It is mainly used in computer shell, mobile phone shell, household appliances and other industries. It can be plated with metal film, alloy film, composite film, transparent, translucent film, non-conductive film, electromagnetic shielding film, etc.

Follow the official WeChat

Follow the official WeChat